Understanding Thatching Blades

What is a Thatching Blade?

When it comes to maintaining a thatched roof, understanding the role of a thatching blade is crucial—think of it as the surgeon’s scalpel in the world of roofing tools. This specialized blade is designed to delicately trim and shape the thatching material, ensuring a tidy finish and prolonging the lifespan of your roof. Without a sharp, precise thatching blade, the art of thatching becomes a messy affair—think of it as trying to carve a roast with a butter knife!

What makes a thatching blade stand out? Its craftsmanship is tailored for the unique demands of working with straw, reeds, or other natural materials. The blade’s edge is honed to perfection, allowing for clean cuts that prevent unnecessary fraying or damage. Whether you’re a seasoned thatcher or a weekend warrior, recognizing the importance of a quality thatching blade can mean the difference between a roof that lasts decades and one that needs constant repairs. After all, a good thatching blade isn’t just a tool; it’s an artist’s brush in the hands of a skilled craftsman.

For those looking to elevate their thatching game, here’s a quick overview of what a thatching blade typically entails:

- Sharp, durable cutting edge designed for natural materials

- Ergonomic handle for comfortable, extended use

- Precision manufacturing to ensure clean, consistent cuts

Components and Materials of a Thatching Blade

Understanding the components and materials of a thatching blade reveals why this tool is revered among skilled thatchers. Crafted with precision, the blade’s core is often forged from high-carbon steel, offering the perfect balance of strength and flexibility—qualities essential for working with natural materials like reeds and straw. The durability of these blades ensures they maintain a sharp edge through countless projects, a testament to their expert manufacturing.

The blade’s edge is meticulously honed, sometimes featuring a beveled or straight cutting edge tailored specifically for thatching. The handle, often made from seasoned hardwood or lightweight composites, is ergonomically designed to reduce fatigue during extended use. This thoughtful construction guarantees that every cut is clean and controlled, preventing fraying or damage to the delicate thatching material.

In essence, the materials and components of a thatching blade are carefully chosen, blending artistry with engineering. When selecting a thatching blade, attention to these details can transform the craft—turning a simple task into a seamless expression of craftsmanship. Recognizing the significance of high-quality components is what elevates a good thatching blade into an indispensable tool for every thatcher’s arsenal.

Different Types of Thatching Blades

Understanding the tapestry of thatching blades reveals a symphony of craftsmanship, where each type plays its unique part in the artistry of roof making. In the wilds of South Africa, where traditional thatching persists as a cultural cornerstone, selecting the right thatching blade can elevate a simple task to a dance of precision and grace. The variety of thatching blades available is as diverse as the natural materials they’re designed to shape—each tailored to the specific demands of reed, straw, or grass.

Among the most revered are the classic straight-edged blades, celebrated for their simplicity and versatility. These blades glide effortlessly through dense thatching materials, offering a clean cut that ensures longevity and aesthetic appeal. Conversely, beveled-edged thatching blades have gained popularity for their ability to slice through tougher, fibrous materials with minimal effort. It’s these distinctions that make understanding the different types of thatching blades essential for every craftsman committed to excellence.

To truly appreciate the variety, consider this:

- 1. The traditional straight blade, perfect for delicate reeds.

- 2. The curved or beveled blade, designed for resilient straw or grasses.

- 3. The heavy-duty blade, reserved for the most demanding projects requiring robust strength.

Each of these thatching blades embodies a harmony of engineering and artistry, ensuring that every cut is a stroke of mastery. Whether shaping a humble South African rondavel or restoring a historic thatched roof, understanding the different types of thatching blades unlocks a world where craftsmanship and tradition intertwine seamlessly.

Uses and Applications of Thatching Blades

Traditional Thatching in Roofing

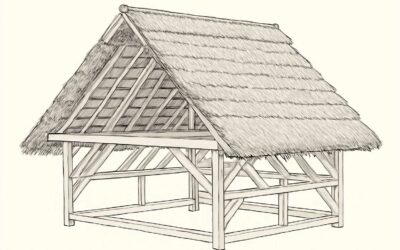

Thatching blades have been the unsung heroes of South African roofing for centuries—sometimes literally holding up entire communities’ roofs! Their primary purpose? To turn the art of thatching into an efficient, precise craft. Whether you’re restoring a heritage homestead or constructing a new eco-friendly dwelling, a quality thatching blade is essential for shaping and trimming thatch with surgical accuracy.

In traditional thatching, the blade’s applications go beyond mere cutting. It’s about sculpting natural materials like straw, reeds, or grass into watertight works of art. The right thatching blade ensures neatness and durability, transforming wild grasses into a tightly woven shelter that can withstand South Africa’s fierce sun and seasonal storms. From creating intricate ridges to trimming excess thatch, these blades are versatile tools that blend craftsmanship with resilience.

For those committed to authentic roofing, employing a thatching blade in your workflow means embracing a technique rooted in history yet perfectly suited for modern sustainability. No matter if you’re a seasoned thatcher or a passionate DIY enthusiast, this tool is indispensable for achieving thatch roofs that stand the test of time and weather—proof that tradition and innovation can go hand in hand.

Landscaping and Garden Maintenance

Beyond the traditional rooftops, the versatility of a thatching blade finds a fascinating place in landscaping and garden maintenance. Its precise edge and sharpness allow for meticulous pruning and shaping of natural elements, transforming gardens into living sculptures. Whether trimming ornamental grasses or shaping hedges with finesse, the thatching blade elevates garden craftsmanship to an art form. This tool’s resilience and sharpness ensure clean cuts that promote healthy growth, making it indispensable for professional landscapers and passionate gardeners alike.

In addition to shaping plants, the thatching blade excels at removing dead or overgrown foliage, helping to maintain a lush, vibrant landscape. Its ability to handle coarse, fibrous materials makes it ideal for tasks such as clearing thatch buildup in garden beds or managing reed borders. For those seeking to create natural water features or eco-friendly landscaping, this tool offers the precision needed to sculpt reed fences or natural barriers seamlessly.

Its application extends to garden restoration projects where meticulous trimming preserves the aesthetic integrity of a space. Whether crafting intricate reed screens or maintaining thatched garden structures, the versatility of a thatching blade ensures every detail is executed with surgical accuracy. This blend of craftsmanship and resilience truly makes the thatching blade a cornerstone of sustainable, authentic garden design in South Africa.

Agricultural Uses

In the realm of agriculture, the thatching blade emerges as an indispensable tool—its sharp, resilient edge transforming routine tasks into precise operations. From clearing coarse reed and tall grasses to shaping natural barriers, the thatching blade’s versatility is unmatched. Farmers and landscapers alike rely on its ability to handle fibrous, tough materials with surgical accuracy, ensuring healthy growth and a pristine aesthetic.

Its applications extend far beyond mere trimming. The thatching blade is crucial in managing reed beds and creating natural fencing, seamlessly blending functionality with eco-friendly design. For those involved in sustainable farming or organic landscaping, this tool becomes a silent partner, facilitating the creation of natural water features and eco-conscious garden structures.

- Removing overgrown or dead foliage to promote vitality

- Shaping reed fences and borders for aesthetic appeal

- Clearing thatch buildup in garden beds or natural wetlands

In South Africa’s diverse agricultural landscape, the thatching blade’s robustness and versatility make it a cornerstone for sustainable practices. Its ability to adapt to various fibrous materials ensures that every cut is clean, every shape precise—an essential for professionals striving for excellence amidst nature’s complexity. Truly, the thatching blade embodies the essence of craftsmanship in the field of agricultural maintenance, making it a vital asset for cultivating vitality and beauty in every plot of land.

Choosing the Right Thatching Blade

Factors to Consider Before Buying

In the mystical landscape of South Africa, where the sun’s relentless gaze bends the earth to its will, choosing the right thatching blade becomes an act of silent reverence. Did you know that the quality of your thatching blade can determine the longevity of a roof or the lushness of a garden? It’s as if each blade carries a whisper of ancient craftsmanship, woven with the promise of durability and precision. When selecting a thatching blade, one must consider not only the material but also the craftsmanship behind it, for these elements forge a tool capable of transforming raw materials into art.

Factors to consider before buying include the blade’s edge sharpness, durability, and compatibility with the task at hand. For instance, a lawn thatching blade used for garden maintenance must possess a keen edge that slices through thatch with ease, yet withstand the rigors of frequent use. Sometimes, the difference lies in the blade’s design—whether it features a traditional curved form for sweeping tasks or a straight edge for detailed work. Recognizing these nuances ensures that every cut is clean, every thatch is expertly managed, and the tool becomes an extension of one’s own mastery.

Compatibility with Various Tools

Choosing the right thatching blade isn’t just a matter of picking the sharpest tool in the shed; it’s about ensuring seamless compatibility with your existing garden or roofing arsenal. A mismatched blade can turn a simple maintenance task into an exercise in frustration, or worse, damage the very materials you’re trying to preserve. For those who value precision and longevity, understanding which thatching blade suits your tools is paramount.

Most thatching blades are designed to fit specific types of equipment, whether it’s a traditional rake, a power thatching tool, or a specialized garden fork. Compatibility hinges on factors like blade size, mounting mechanism, and cutting edge design. Some blades feature a universal fit, making them versatile for multiple tools, while others are tailored for niche applications. Recognizing these nuances can save time, money, and a lot of sweat in the garden or on the roof.

To streamline your selection, consider the following:

- The type of task—are you maintaining a lush lawn or repairing a thatched roof?

- The specific tool you own—does the blade need to slide into a slot or bolt onto a frame?

- The material and craftsmanship—does your blade boast hardened steel or a corrosion-resistant coating?

Ultimately, the goal is a harmonious union between your thatching blade and your equipment—because in the world of South African thatching and landscaping, compatibility is king. When your blade matches your tool, every cut becomes a symphony of efficiency and finesse, turning mundane chores into moments of mastery.

Maintenance and Durability

Choosing the right thatching blade is an act of precision, a delicate balance between resilience and finesse. When a blade’s durability is compromised, even the most skilled gardener or roofer risks undoing their meticulous work. The secret lies in understanding thatmaintenance and durability are intertwined; a well-cared-for thatching blade can transform mundane chores into moments of mastery.

Durability begins with the material—hardened steel and corrosion-resistant coatings extend the lifespan of your thatching blade, especially in South Africa’s challenging climate. Regular sharpening and cleaning are essential, ensuring the cutting edge remains sharp, reducing strain on your tools and preventing unnecessary wear.

In the end, selecting a thatching blade that aligns with your specific needs isn’t just about efficiency; it’s about respecting the craftsmanship behind each cut. A quality blade, maintained with care, becomes an extension of your commitment—an enduring tool that stands the test of time, whether on the roof or in the garden.

Popular Brands and Manufacturers

Top Manufacturers of Thatching Blades

When it comes to choosing a thatching blade, the brands behind these tools can make all the difference in performance and longevity. Top manufacturers have earned their reputation through decades of innovation, precision engineering, and unwavering quality standards. In South Africa, the demand for durable thatching blades is growing, especially among landscapers and agricultural professionals who rely on these tools daily.

Some of the most trusted names in the industry include Fiskars, Bahco, and Wilkinson Sword. These brands are renowned for producing thatching blades that combine cutting-edge materials with ergonomic design, ensuring both efficiency and safety. Their products are tailored to withstand harsh conditions, from rugged garden tasks to heavy-duty roofing projects.

For those seeking a reliable thatching blade, it’s worth exploring the top manufacturers in the market. They often offer a range of options, from traditional steel blades to modern, corrosion-resistant variants. The right choice will depend on your specific needs, but opting for established brands guarantees a level of quality that’s hard to match.

Features of Reputable Brands

Among the ranks of reputable brands, certain names stand as beacons of excellence in the world of thatching blades. Fiskars, Bahco, and Wilkinson Sword are not merely manufacturers—they are artisans dedicated to precision, innovation, and durability. Their thatching blades are crafted for professionals who demand nothing but the best, whether for intricate roofing or rugged garden tasks. These brands have built their reputation on a foundation of quality and trust, ensuring each thatching blade performs flawlessly under pressure.

What sets these brands apart? It is their relentless pursuit of perfection through advanced materials and ergonomic design. Features of reputable brands include corrosion-resistant coatings, razor-sharp edges, and ergonomic handles that reduce fatigue during prolonged use. Such features elevate the thatching blade from a simple tool to an extension of the craftsman’s skill.

- Modern manufacturing techniques ensure consistent quality

- Use of high-grade steel for longevity and resilience

- Specialized coatings to withstand harsh environmental conditions

Choosing a thatching blade from a top manufacturer guarantees a harmonious blend of efficiency and safety—a true testament to their mastery in toolmaking. In the landscape of South Africa’s vibrant agricultural and gardening sectors, these brands continue to set the standard, inspiring confidence with every cut. When a thatching blade bears the mark of a trusted name, you embrace a legacy of excellence that transforms every task into a work of craftsmanship.

Price Range and Value for Money

In the bustling markets of South Africa’s agricultural and gardening sectors, the price of a thatching blade often mirrors its craftsmanship and brand reputation. While some budget-friendly options can be found, investing in a reputable brand typically guarantees superior performance, durability, and safety. Top manufacturers like Fiskars, Bahco, and Wilkinson Sword offer a spectrum of thatching blades that cater to both professional landscapers and passionate hobbyists.

Price ranges for quality thatching blades vary widely, from affordable entry-level tools to high-end, industrial-grade blades. Generally, you can expect to pay between R150 and R600 depending on the brand, material quality, and specific design features. The allure of value for money becomes evident when considering the longevity and efficiency a high-quality thatching blade provides. A well-crafted blade from a trusted manufacturer can last for years, making it a worthwhile investment that outperforms cheaper, disposable alternatives.

- Entry-level thatching blades: R150 – R250 – suitable for light tasks and occasional use.

- Mid-range options: R250 – R400 – ideal for regular gardening or landscaping professionals.

- Premium blades: R400 – R600+ – designed for intensive agricultural work and demanding environments.

What truly elevates a thatching blade from merely a tool to a masterpiece is the inherent value it offers—combining cutting-edge materials, ergonomic design, and craftsmanship. When you select a thatching blade from a reputable manufacturer, you’re not just purchasing a blade; you are embracing a legacy of excellence that seamlessly marries efficiency with safety. It’s a choice that transforms everyday tasks into an artful dance of precision and resilience—an essential within South Africa’s vibrant landscape of growth and renewal.

How to Use a Thatching Blade Safely and Effectively

Preparation and Safety Tips

In the realm of traditional craftsmanship, the thatching blade stands as a mystical instrument, wielded with precision and care. To harness its full potential safely and effectively, one must first embrace a ritual of preparation. Ensuring the thatching blade is sharp and free of rust not only enhances its performance but also shields the user from unnecessary mishaps. Wearing sturdy gloves and eye protection becomes an integral part of this sacred process, warding off the splinters and shards that may arise during the cutting dance.

Before embarking on the task, clear the workspace of obstacles, and secure the material to prevent any unexpected slips. Remember, the key to mastery lies in controlled movements—always cut away from your body, maintaining a firm grip on the handle. For those unfamiliar with the nuances of this tool, an ordered approach can be invaluable:

- Inspect the thatching blade for damage or dullness.

- Sharpen or replace it as needed to ensure optimal cutting power.

- Secure the thatch or material firmly to prevent shifting during work.

- Use smooth, deliberate strokes to avoid fatigue and accidental slips.

With patience and vigilance, the art of using a thatching blade becomes second nature—transforming a simple task into a craft that venerates tradition while ensuring safety and efficiency at every cut.

Proper Handling Techniques

Mastering the thatching blade is an act of both precision and reverence—an intimate dance between human intent and the raw material of nature. To wield this tool with purpose, one must approach it not merely as an implement but as an extension of craftsmanship itself. Proper handling techniques elevate the task from mundane labor to an expression of tradition and skill. The secret lies in understanding the subtle language of the thatching blade, where every movement can either honor or compromise the integrity of the work.

When using a thatching blade, ensure your grip is firm but relaxed, allowing for controlled, deliberate strokes. Always cut away from your body to preserve safety, and maintain a steady hand—this cultivates both precision and confidence. Remember, a sharp, well-maintained thatching blade transforms each cut into a fluid motion, reducing fatigue and minimizing accidents. To enhance safety and effectiveness, consider these steps:

- Inspect the thatching blade for rust or dullness regularly.

- Sharpen or replace it as needed to keep the cutting edge pristine.

- Secure the material firmly to prevent shifting during work.

By embracing these techniques, the art of using a thatching blade becomes a meditative process—one where mastery is born from careful attention, psychological focus, and respect for the tool. In the end, this approach ensures each cut preserves the integrity of the natural materials while upholding the traditions that have endured through generations.

Cleaning and Storage Tips

Handling a thatching blade isn’t just about slicing through natural materials; it’s about respecting a tool that carries centuries of craftsmanship. To use a thatching blade safely and effectively, always inspect it before each session—look for rust, dullness, or any signs of wear that could turn a clean cut into a potential disaster. Sharpness is key, so keep your blade well-maintained and sharpened regularly, ensuring each stroke is smooth and deliberate. Remember, safety is paramount: cut away from your body and maintain a relaxed grip to avoid slips that could ruin your day—and your fingers!

For optimal safety and performance, consider these tips:

- Secure your material firmly, so it doesn’t shift mid-cut, which could cause a mishap.

- Store your thatching blade in a dry, protected place—think of it as giving your trusty tool a spa day after every use.

- Use a blade cover or sheath when not in use to prevent accidental cuts and keep the edge pristine.

Cleaning your thatching blade after each use with a gentle oil prevents rust and preserves the sharpness. Proper storage—preferably hanging or in a toolbox—keeps the blade from dulling prematurely and ensures it’s always ready for the next thatching adventure. With these simple practices, your thatching blade remains a reliable companion, transforming every cut into an act of precision and tradition.

Innovations and Future Trends

Latest Technologies in Thatching Blade Design

Innovation in thatching blade design is transforming how professionals and enthusiasts approach traditional craftsmanship. Cutting-edge technologies now enable the creation of blades that are sharper, more durable, and ergonomically optimized, ensuring precision with every cut. These advancements not only extend the lifespan of the thatching blade but also enhance efficiency, making the task less arduous and more satisfying.

One exciting trend is the integration of high-performance materials such as titanium alloys and advanced composites. These materials offer superior corrosion resistance and lightweight strength, essential qualities for the demanding conditions faced during thatching and landscaping. Additionally, manufacturers are exploring laser-cutting techniques that produce ultra-fine edges, resulting in smoother cuts and less damage to natural materials.

To stay ahead, some brands are now embracing the future with smart tools. Imagine a thatching blade embedded with sensors that monitor wear and alert you when it’s time for a replacement—this is not science fiction but an emerging reality. As technology evolves, the focus remains on creating tools that blend traditional craftsmanship with modern innovation, ensuring that the art of thatching continues to flourish.

Environmental Considerations

As the world turns increasingly conscious of ecological footprints, innovations in thatching blade technology echo this shift with a commitment to sustainability. Future trends are gravitating toward environmentally friendly materials that do not compromise performance, such as biodegradable composites and recycled metals. These advances ensure that craftsmanship remains in harmony with nature, reducing waste and conserving resources.

Environmental considerations are no longer an afterthought—they are woven into the very fabric of modern thatching blade design. Manufacturers are prioritizing eco-conscious production processes, minimizing energy consumption and pollution. In South Africa, where natural materials are revered, this evolution is vital for preserving the authenticity of traditional thatching while embracing modern sustainability.

Moreover, innovative thatching blades now incorporate features aimed at reducing environmental impact, such as:

- Enhanced durability to extend lifespan and decrease frequent replacements

- Lightweight, high-performance materials that lower transportation emissions

- Recyclable components that support circular economy principles

Looking ahead, the intersection of technology and eco-awareness promises a future where the art of thatching is both sustainable and efficient. Smart blades equipped with sensors may soon monitor environmental impact and wear, ensuring optimal use and minimal waste—truly a harmonious blend of tradition and innovation that respects both craftsmanship and our planet.

Emerging Market Trends

Innovations in thatching blade technology are reshaping the future of sustainable craftsmanship. As eco-consciousness gains momentum, manufacturers are developing thatching blades using biodegradable composites and recycled metals. These materials not only enhance performance but also significantly reduce the environmental footprint. Future market trends point toward lighter, more durable blades that cut down on waste and transportation emissions.

Emerging features include smart thatching blades equipped with sensors to monitor wear and environmental impact. This technology ensures that each blade is used efficiently, minimizing waste and extending lifespan. Additionally, circular economy principles are being integrated by designing recyclable components that support sustainable reuse.

- Enhanced durability for longer service life

- Lightweight materials that lower transportation emissions

- Recyclable parts that promote sustainability

As South Africa’s natural materials culture continues to influence design, these advancements ensure that traditional thatching remains authentic while embracing modern eco-innovation. The convergence of technology and eco-awareness is forging a future where the artistry of thatching blade use aligns with global sustainability goals, making craftsmanship more responsible and efficient than ever before.

0 Comments